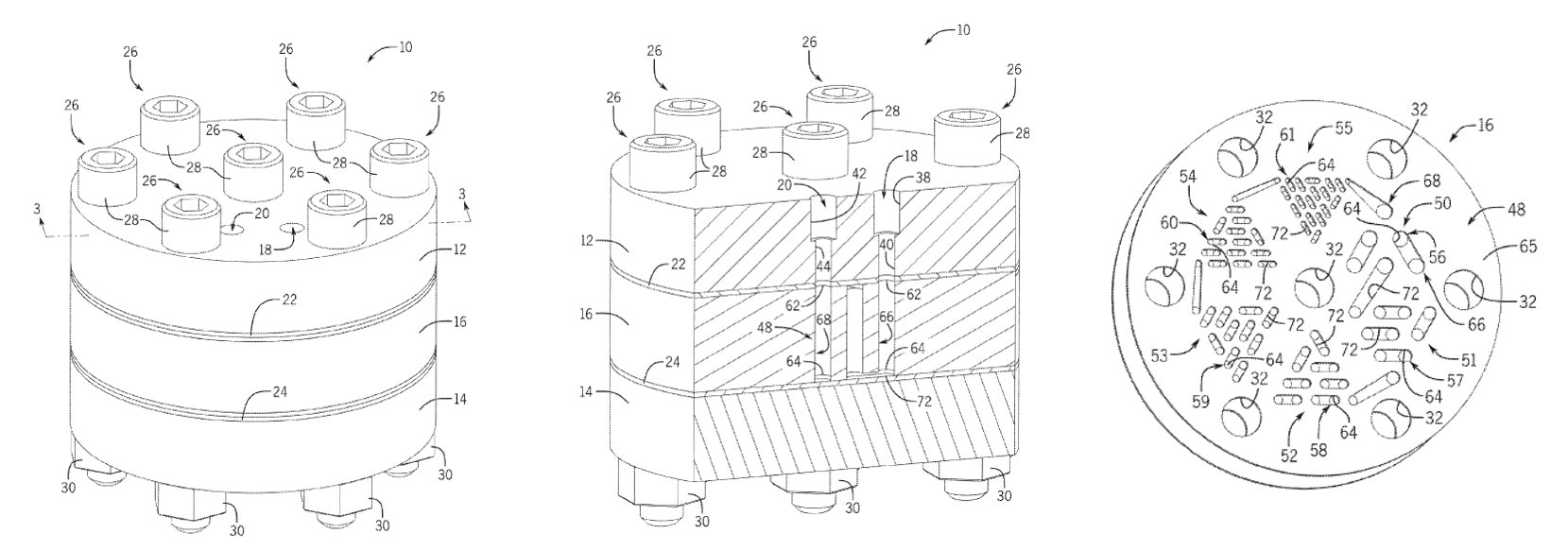

US Patent #9625584 B1

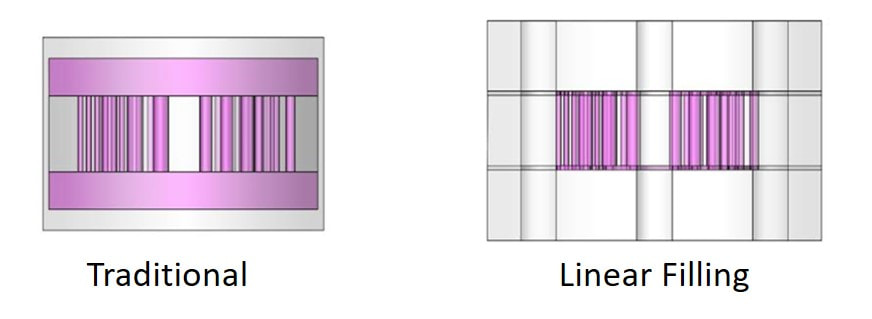

Several of our products, including our Derenzo pattern phantoms, feature patented linear filling technology. The scheme allows for complex hole patterns to be filled linearly, or one hole at a time. This ensures that even small channels get filled evenly and drastically reduces the amount of volume required to fill the phantom. This reduction in volume is safer to handle and reduces the cost of filling phantoms, even paying for the phantom itself in cost savings over time. Check out the resources below for more information.

Linear Filling Explained

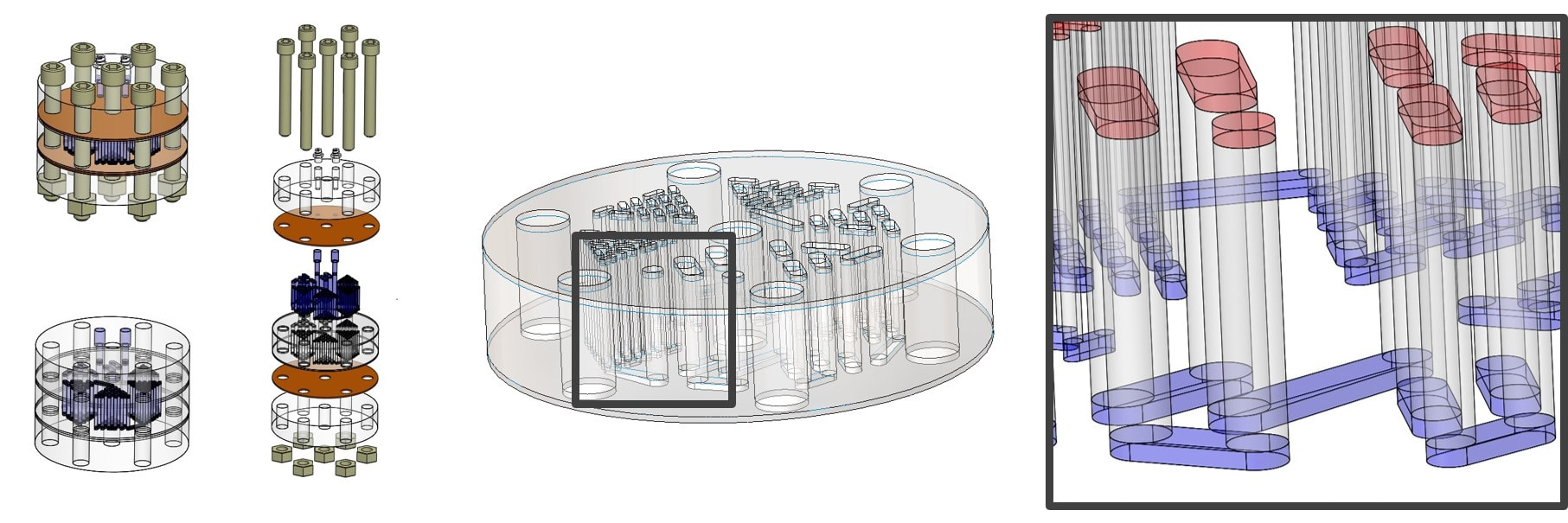

Linear filling is achieved through a piece-wise construction that creates a long snaking channel through the desired phantom. This chain is comprised of both the hot rods that comprise the desired hole pattern, as well as connecting channels to connect neighboring hot rods. With a single inlet and outlet, fluid is easily driven into the phantom using a Luer Lock syringe. This eliminates the need to manually fill small holes that are prone to air bubbles from surface tension.

Furthermore, typical techniques for creating complex hole patterns involve the submersion of the hole pattern in a pool of radioactivity. This technique eliminates the resulting pools of radiation, drastically reducing the internal volume of the phantom and increasing the image quality by removing a major source of background noise. Please refer to the attached paper for further reading on linear filling.

Madison, WI

www.phantechmedical.com

www.phantechmedical.com